CO2 capture for your site

CarbonQuest provides a cost-effective, end-to-end solution that utilizes cutting-edge technology to offset carbon emissions without disrupting site operations.CarbonQuest makes it easier than ever for owners and operators of facilities and onsite distributed power systems to reduce their Scope 1 emissions, lowering their carbon footprint while complying with GHG Protocol and Science Based Targets (SBTi). Our patented carbon capture system is scalable and flexible to fit the needs of most environments.

We trap CO2 that is generated during the routine operation of boilers, fuel cells, combined heat and power systems, and industrial processes. The CO2 is diverted into the CarbonQuest system after combustion and is prevented from entering the atmosphere by the Distributed Carbon Capture™ that liquifies the CO2 on site. The volume of emissions captured varies by customer requirement, with the ability to capture 100% gross output of CO2.

Building Carbon Capture™

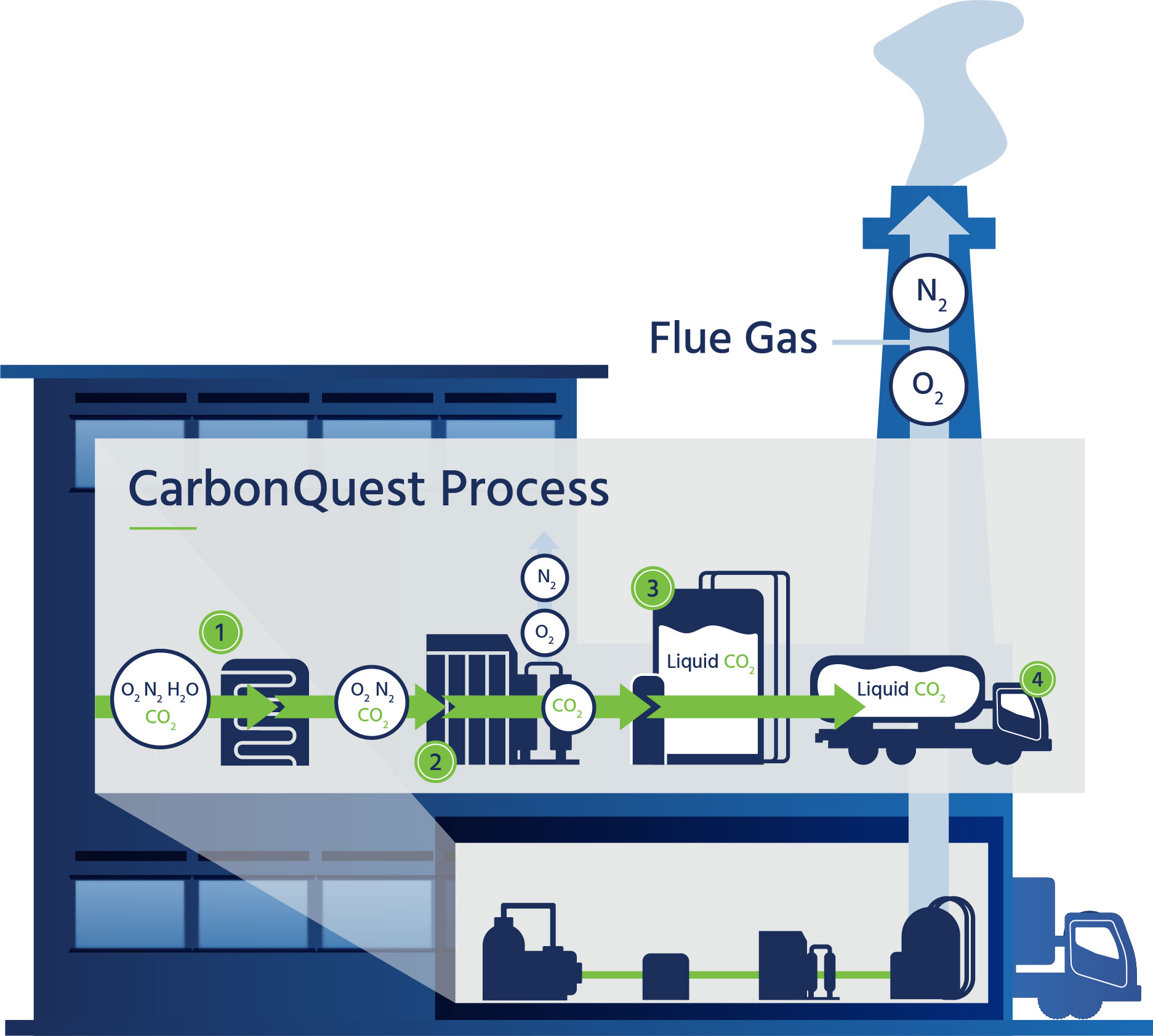

Explore how our integrated four-step process works for carbon capture.

Step 1: Extraction

CO2, O2, N2 and H2O are diverted from the gas flue during regular building operations and sent through a heat exchanger, compressor and dryer, removing H20 before continuing on to the separation phase.

Step 2: Separation

The gasses move through an innovative pressure swing adsorption system that cycles out N2 and O2, releasing them back into the flue as CO2 continues on to the conversion phase.

Step 3: Conversion

The CO2 gas stream then goes through the process of liquefaction onsite, where it’s converted into liquid CO2 before being placed into a storage tank to await transfer.

Step 4: Utilization

The liquid Sustainable CO2™ is regularly transferred to customers who reduce emissions through utilization, enabling a true circular carbon economy within the city.

Step 1: Extraction

CO2, O2, N2 and H2O are diverted from the gas flue during regular building operations and sent through a heat exchanger, compressor and dryer, removing H20 before continuing on to the separation phase.

Step 2: Separation

The gasses move through an innovative pressure swing adsorption system that cycles out N2 and O2, releasing them back into the flue as CO2 continues on to the conversion phase.

Step 3: Conversion

The CO2 gas stream then goes through the process of liquefaction onsite, where it’s converted into liquid CO2 before being placed into a storage tank to await transfer.

Step 4: Utilization

The liquid Sustainable CO2™ is regularly transferred to customers who reduce emissions through utilization, enabling a true circular carbon economy within the city.

Decarbonizing Communities

Integrating with other sustainable solutions to fuel faster emission reduction and energy savings.Decarbonizing our communities is hard work. CarbonQuest’s solution integrates with other important pathways such as onsite renewables, energy efficiency and energy management, and partial electrification. Our innovative system can draw power from onsite solar, and our software can feed into existing energy management systems to enhance the energy efficiency of the building.

Featured Project

1930 Broadway1930 Broadway is a multifamily building located in Manhattan’s Lincoln Square neighborhood. CarbonQuest installed its onsite carbon capture technology in the building in 2021 with a goal of cutting CO2 emissions from natural gas usage by 60-70%.